21-May-2025

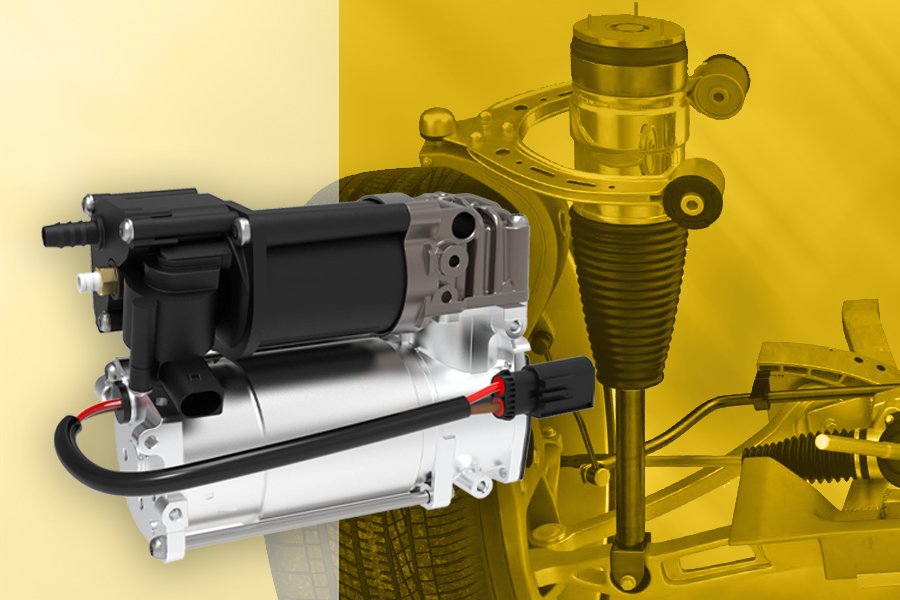

Magneti Marelli Parts & Services launches a new range of compressors, thus completing the range of spare parts for vehicles with air suspensions

Inclusion of 54 compressor part numbers, covering the needs of the premium circulating vehicle park equipped with air suspensions

Manufactured in state-of-the-art plants intended for air suspension compressors, these products are made from high-quality materials and subject to rigorous testing

Available in a variety of configurations, the compressors are boxed in the unmistakable yellow and blue packaging; in addition, each product is marked with the laser-printed Magneti Marelli Parts & Services logo, a guarantee of excellence and reliability

Magneti Marelli Parts & Services is expanding its aftermarket range of spare parts for air suspension systems by adding to its catalogue compressors, key elements for vehicle trim control. With this new product offering, Magneti Marelli Parts & Services now offers aftermarket spare parts for the entire air suspension system, which also includes air springs, air dampers and oil-gas shock absorbers.

Magneti Marelli Parts & Services' offering of air suspension compressors currently includes 54 carefully selected part numbers to meet the needs of vehicles equipped with air suspensions, which are generally adopted by premium manufacturers, particularly from Germany and the UK.

Boxed in the highly recognizable yellow and blue packaging, Magneti Marelli Parts & Services compressors are available in different configurations associated with multiple part numbers. Packaging variants can include the mounting bracket alone or a more complete version with valves, installation wiring, relays and dryer (the latter included as standard in all configurations).

Their quality is guaranteed by production in dedicated facilities, where each compressor undergoes a series of rigorous tests to ensure optimal performance under all conditions. In addition to fatigue and strength tests, each compressor is evaluated through performance and vibration tests.

Thermal variations, from a maximum of 85 °C to a minimum of -40 °C, are also conducted, ensuring the product's resistance to thermal shocks. The stresses are monitored with appropriate instrumentation to ensure reliability even in extreme conditions. These procedures are combined with an advanced design that reduces noise and vibration but also offers robust protection against external contamination by particles, liquids and microorganisms. As a result, these products have a degree of protection, in line with OE manufacturers' standards. All these features ensure that the compressors are always up to the expectations of quality, reliability and durability required by premium vehicles.

The high and consistent performance of air compressors offered by Magneti Marelli Parts & Services is the result of state-of-the-art design and the use of materials selected for their high strength. Die-cast aluminum is used to optimize heat dissipation, steel undergoes anti-corrosion treatments, and brass completes the construction to ensure strength. Silent operation, comfort and durability are the key features of these compressors, along with the excellent value for money that characterizes all Magneti Marelli Parts & Services products.

The compressors offered on the market by Magneti Marelli Parts & Services ensure short installation times and comprehensive technical support for professionals: the packaging includes detailed assembly instructions, designed to make the installation of the product and its components as easy as possible, ensuring optimal operating efficiency.

Operation, optimization and reliability

In an air suspension system, the compressor has the key role of generating and maintaining the pressure necessary for the air springs to operate, working in synergy with an electronic control unit (ECU) that manages its operation based on the driving and loading conditions of the car. The compressor optimizes pressure delivery to adapt the vehicle's stance according to different driving contexts and to dynamically adjust the suspension height, while the stiffness of the car varies according to the air pressure and to the interaction with other components in the system. The rugged design of Magneti Marelli Parts & Services’ compressors, combined with high quality electronic components, results in great resistance to stress, but also in reliability and consistency of performance, essential features to ensure the indispensable safety of driving under all conditions of vehicle use.

Integration with diagnostic systems and safety

The compressors in the Magneti Marelli Parts & Services range are designed to ensure full integration with the main diagnostic systems on the market to make it easier for professionals to investigate potential problems. However, it is essential that when replacing the compressor, the mechanic always checks the efficiency of all other components of the air suspension system to ensure maximum safety for the vehicle user. In this context, the compressor can malfunction either through its own causes or as a result of faults in other system components, such as leaks from bellows or valves, which can cause it to overwork and accelerate wear.

With the introduction of the compressors range, Magneti Marelli Parts & Services further expands its offering and completes its catalogue of components for air suspension systems, ensuring that professionals can provide a comprehensive service to customers.

-

NEWS2026-02-10Magneti Marelli Checkstar on Netflix: the miniseries “Motorvalley” is now streaming

-

NEWS2026-01-22Oiltek 2025: Magneti Marelli Parts & Services heads to New York with Italian distributors and spare parts dealers

-

NEWS2025-12-11Magneti Marelli Parts & Services expands its product range for the latest Chinese vehicle models

-

NEWS2025-12-05Magneti Marelli Parts & Services offers a complete range of shock absorbers and cutting-edge solutions for next-generation vehicles

-

NEWS2025-11-20Nicolò Bulega, Runner-up in the 2025 World Superbike Championship: 14 Victories in Magneti Marelli Checkstar Colors

-

NEWS2025-11-14Barcelona ignites passion: the exclusive experience for polish partners of Magneti Marelli Parts & Services

-

NEWS2025-11-08Antonio Giovinazzi – Brand Ambassador for Magneti Marelli Parts & Services – Triumphs in the 2025 WEC Drivers’ Championship

-

NEWS2025-10-08Magneti Marelli Parts & Services offers a comprehensive and strictly OE range of rear-view mirrors