09-July-2025

Magneti Marelli Parts & Services launches a new range of turbochargers

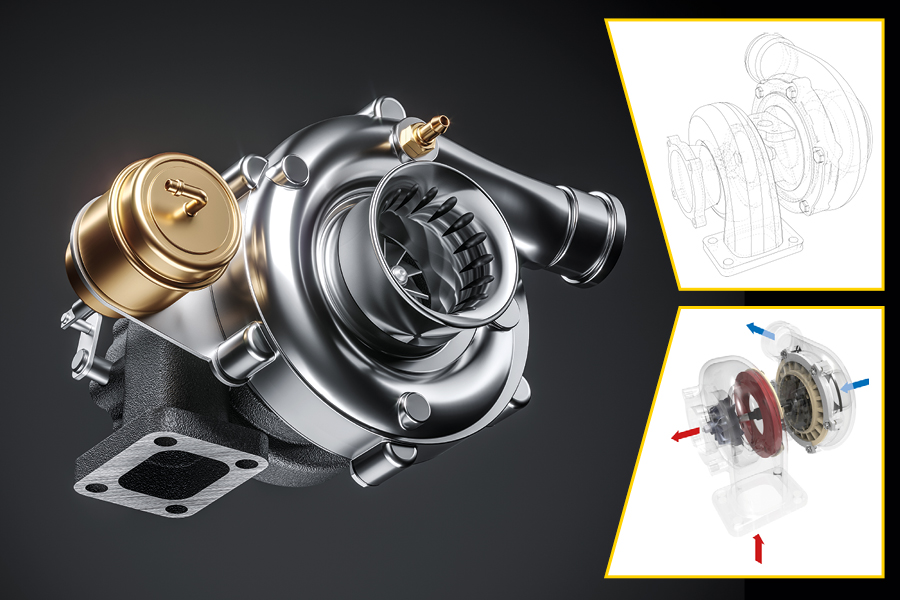

Magneti Marelli Parts & Services is expanding its offering for the independent aftermarket sector with the introduction of a new range of turbochargers. These are characterised by OE-equivalent quality, and broad application coverage.

—Wide coverage and engine availability

The new range from Magneti Marelli Parts & Services covers twenty brands, both Italian (Alfa Romeo, Fiat, Lancia) and foreign (Audi, BMW, Citroën, Dacia, Ford, Hyundai, Mercedes-Benz, Nissan, Opel, Peugeot, Renault, Seat, Skoda, Toyota, Volkswagen, and Volvo), and an extensive array of engine types for each model, starting with popular engines like the 1.3 MultiJet engines from Alfa Romeo, Fiat, and Lancia, and the 2.0 TDI engines used by Volkswagen Group brands. Additionally, turbochargers dedicated to commercial vehicles from Citroën, Fiat, Ford, Iveco, Mercedes-Benz, Opel, Peugeot, Renault, and Volkswagen are included. The range update will continue on an ongoing basis to maintain high application coverage and respond to the evolution of engines on the market.

—Technical support and simplified installation for workshops

To facilitate the installation by professionals, Magneti Marelli Parts & Services turbochargers, packaged in the iconic yellow and blue box, come fully equipped with a gasket kit. Replacing a turbocharger requires special attention in the preparation stages, starting with a complete check of the lubrication system and ending with an initial start-up procedure based on a specific protocol. For this reason, the company also provides precise technical guidance and dedicated support, ensuring repairers have the necessary tools to operate according to the highest professional standards.

—OE quality and advanced technology for high performance

Manufactured in facilities certified to ATF 16949 standards, Magneti Marelli Parts & Services turbochargers for the aftermarket benefit from Marelli Group’s OE expertise, a leader in designing and producing actuators for major global OEMs.

Each component is developed using state-of-the-art materials and construction solutions, starting with the impellers, made from Nickel-Chrome alloys capable of withstanding extreme thermomechanical stresses, with temperatures exceeding 900°C on the turbine side.

This range is characterized by the advanced metallurgy of the impellers, whose precision balancing ensures operation up to 200,000 RPM; precision high-roll bearing assemblies with micrometric tolerances, aimed at achieving maximum rotational stability; specific surface treatments offering resistance to the highest temperatures; and optimized duct geometries for the best fluid dynamic efficiency. Additionally, they include wastegate valve actuators calibrated to OE specifications for boost control.

Each Magneti Marelli Parts & Services unit undergoes performance testing on test benches, with complete thermal cycles that validate its dynamic balancing, pressure retention, fluid dynamic performance, and actuator response.

This comprehensive evaluation ensures a reliable, high-performance, and installation-ready product for the aftermarket.

-

NEWS2026-02-10Magneti Marelli Checkstar on Netflix: the miniseries “Motorvalley” is now streaming

-

NEWS2026-01-22Oiltek 2025: Magneti Marelli Parts & Services heads to New York with Italian distributors and spare parts dealers

-

NEWS2025-12-11Magneti Marelli Parts & Services expands its product range for the latest Chinese vehicle models

-

NEWS2025-12-05Magneti Marelli Parts & Services offers a complete range of shock absorbers and cutting-edge solutions for next-generation vehicles

-

NEWS2025-11-20Nicolò Bulega, Runner-up in the 2025 World Superbike Championship: 14 Victories in Magneti Marelli Checkstar Colors

-

NEWS2025-11-14Barcelona ignites passion: the exclusive experience for polish partners of Magneti Marelli Parts & Services

-

NEWS2025-11-08Antonio Giovinazzi – Brand Ambassador for Magneti Marelli Parts & Services – Triumphs in the 2025 WEC Drivers’ Championship

-

NEWS2025-10-08Magneti Marelli Parts & Services offers a comprehensive and strictly OE range of rear-view mirrors