11-September-2025

Magneti Marelli Parts & Services expands its portfolio with a wide range of oil pumps

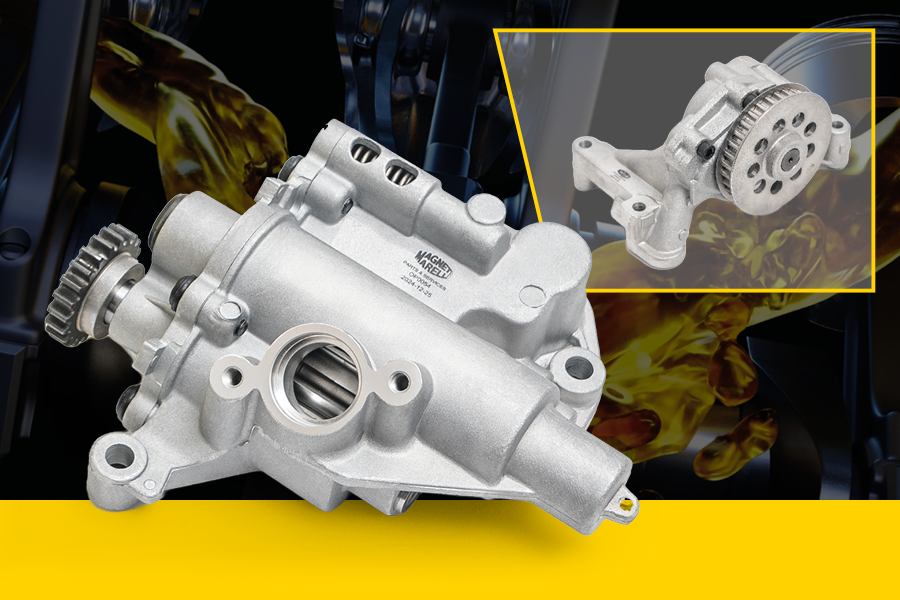

Magneti Marelli Parts & Services is now expanding its offerings in the aftermarket sector by providing a wide range of oil pumps suitable for the majority of vehicles on the road.

— Quality excellence and advanced technology

Magneti Marelli Parts & Services' oil pumps are distinguished by the precision of their design and the use of high-quality materials. Through advanced powder metallurgy techniques, complex geometries are achieved in the production of gears and rotors, while ADC12 aluminum is used for bodies and covers. These premium metal alloys ensure absolute precision of components, long-term maintenance of dimensional tolerances, high resistance to mechanical and thermal wear, stable pressure at all rotational speeds, and corrosion protection.

— Solutions for every need

Equipped with high-precision regulating valves, the oil pumps from Magneti Marelli Parts & Services consistently operate within optimal parameters regardless of load and temperature. They are manufactured in specialized facilities, where every unit undergoes rigorous quality checks. Like all Magneti Marelli Parts & Services spare parts, these pumps come in the distinctive yellow and blue packaging, ensuring protection and environmental compliance. The Magneti Marelli Parts & Services range includes three types of oil pumps, developed to meet the various architectures adopted by original equipment manufacturers:

¬ Gear pumps, available in internal or external gear configurations. The calibrated tooth profile reduces vibrations and noise, while the precise gear engagement minimizes internal friction, ensuring a stable flow even at high rotational speeds.

¬ Rotor pumps, consisting of an internal rotor and an external rotor mounted with defined eccentricity. The rotor geometry and strict tolerance control ensure high volumetric efficiency, while surface treatments enhance wear resistance, even under harsh conditions such as cold starts.

¬ Variable displacement vane pumps, which automatically adjust oil flow based on engine operating conditions. The control of eccentricities between the rotor and stator optimizes lubrication and cooling, contributing to overall efficiency improvements to reduce fuel consumption and emissions.

— When replacement is needed

The efficiency of the oil pump is generally assured up to 150,000 kilometers, but it can decrease if lubricant or filter replacements are not performed at recommended intervals, or following extraordinary stresses or mechanical damage to the vehicle. Reduced efficiency is indicated by a drop in oil pressure in the circuit, leading to an increase in operating temperature. In such cases, prompt intervention is crucial, with pump replacement necessary to ensure engine reliability and protection.

-

NEWS2026-02-10Magneti Marelli Checkstar on Netflix: the miniseries “Motorvalley” is now streaming

-

NEWS2026-01-22Oiltek 2025: Magneti Marelli Parts & Services heads to New York with Italian distributors and spare parts dealers

-

NEWS2025-12-11Magneti Marelli Parts & Services expands its product range for the latest Chinese vehicle models

-

NEWS2025-12-05Magneti Marelli Parts & Services offers a complete range of shock absorbers and cutting-edge solutions for next-generation vehicles

-

NEWS2025-11-20Nicolò Bulega, Runner-up in the 2025 World Superbike Championship: 14 Victories in Magneti Marelli Checkstar Colors

-

NEWS2025-11-14Barcelona ignites passion: the exclusive experience for polish partners of Magneti Marelli Parts & Services

-

NEWS2025-11-08Antonio Giovinazzi – Brand Ambassador for Magneti Marelli Parts & Services – Triumphs in the 2025 WEC Drivers’ Championship

-

NEWS2025-10-08Magneti Marelli Parts & Services offers a comprehensive and strictly OE range of rear-view mirrors